| Location | Hyderabad |

| Segment | Residential Complex |

| Old Technology Used | Rotating Moving Bed Biofilm Reactors (RMBR) |

| New Technology Used | Membrane Bio Reactor (MBR) |

| Plant Capacity | 2000 KLD |

| Execution Timeline | 120 Days |

The Challenge

A large residential township in Hyderabad, home to 2,700 apartments, was struggling with its 2,000 KLD sewage treatment plant (STP). Despite the investment in infrastructure, the plant was unreliable and inefficient.

- Regulatory Non-Compliance: The township was unable to meet Telangana State Pollution Control Board (TSPCB) standards.

- Freshwater Dependence: Every summer, residents paid for expensive water tankers due to inadequate recycling.

- High Costs: Frequent breakdowns, chemical overuse, and high energy bills made operations unsustainable.

- Odour & Resident Discomfort: Poor treatment led to odour problems and declining confidence among residents.

- Lack of Skilled Resources: No dedicated team was available to manage the plant effectively.

The result? Rising costs, compliance risks, and frustrated residents.

The Megaliter Approach

Instead of asking the township to spend heavily on upgrades, Megaliter Varunaa stepped in with an investment-backed OPEX model.

- We funded the upgrade of the old system with state-of-the-art Membrane Bioreactor (MBR) technology, ensuring reliability and efficiency.

- We took full operational ownership — daily running, repairs, energy optimisation, chemical management, manpower, and monitoring are all under our umbrella.

- We guaranteed compliance and performance through real-time monitoring and transparent reporting.

In short, the township didn’t need to worry about technology, people, or money — we took care of everything.

The Results

| Parameter | Before | After Megaliter’s Integration |

|---|---|---|

| BOD | 200 mg/l | <10 mg/l |

| COD | 400 mg/l | <30 mg/l |

| TSS | 800 mg/l | 1 mg/l |

| TN | >200 mg/l | <5 mg/l |

| O&G | 20 mg/l | <10 mg/l |

The STP now consistently treats 100% of sewage load and produces high-quality treated water suitable for reuse, with odour-free operations.

The Benefits to the Township

- Financial Savings

- No upfront capital required — Megaliter funded the upgrade.

- Reduced tanker dependence, lowering water costs year-round.

- Lower per-KL treatment costs through energy and chemical optimisation.

- Regulatory & Operational Peace of Mind

- Consistent compliance with TSPCB standards.

- Stress-free operations — Megaliter handles everything end-to-end.

- Water Security & Sustainability

- Reliable supply of treated water for reuse, reducing freshwater dependence.

- Smaller environmental footprint through advanced, space-efficient MBR technology.

The Promise

Today, residents of this township no longer face the anxiety of summer water shortages or the hassle of managing a failing STP. With Megaliter Varunaa’s investment and long-term O&M model, they enjoy reliable water security, compliance, and true peace of mind.

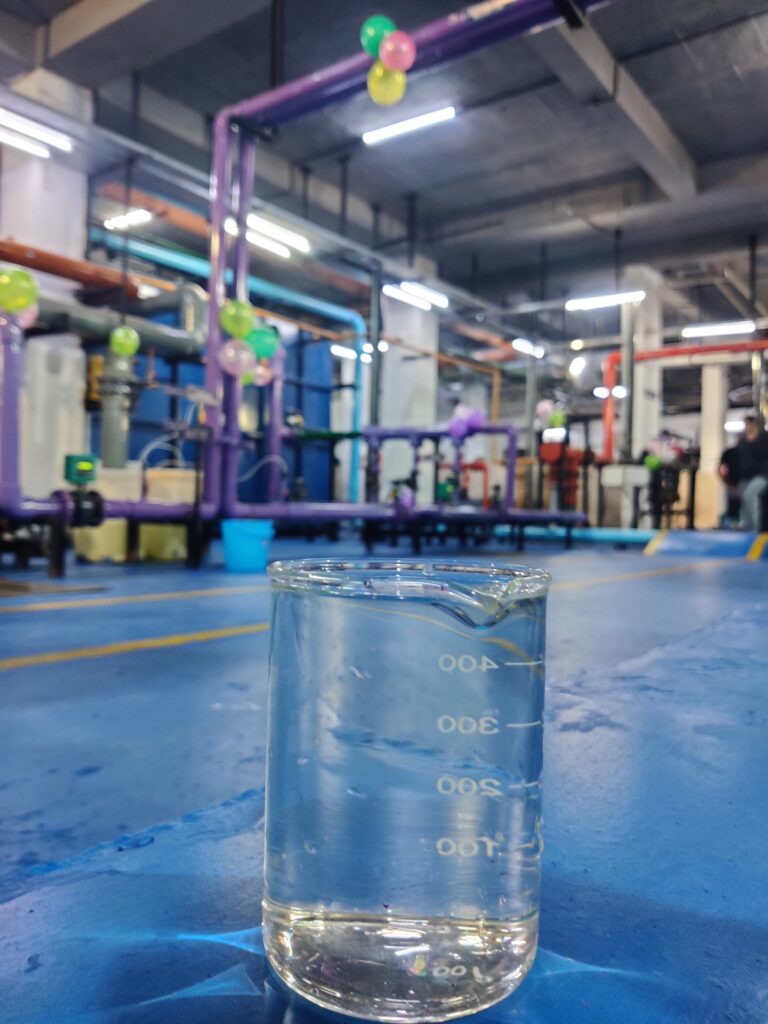

The After

The Before

Let us take the stress out of wastewater management.

With our investment-backed model and long-term O&M expertise, your community can enjoy reliable, compliant, and cost-efficient water reuse.

Schedule a consultation today!